Optimizing Performance: The Relevance of Genuine Komatsu Undercarriage Parts

Optimizing Performance: The Relevance of Genuine Komatsu Undercarriage Parts

Blog Article

Efficient Solutions: Undercarriage Components for Heavy Equipment

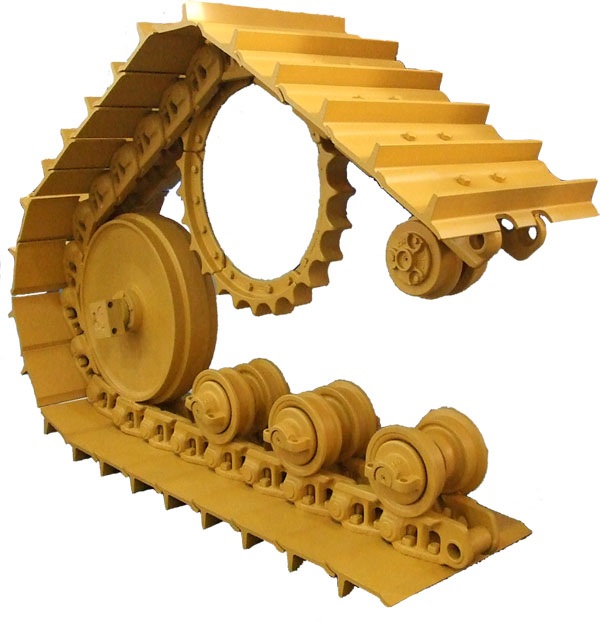

When it pertains to heavy equipment, the undercarriage is an essential element that typically identifies the overall performance and performance of the devices. Quality undercarriage components play a significant role in ensuring the smooth operation and long life of heavy machinery. From excavators to dozers, each tool depends greatly on its undercarriage to hold up against difficult working conditions. Nevertheless, wear and tear are inevitable, causing potential concerns that can hinder performance and boost upkeep expenses (komatsu undercarriage parts). In this conversation, we will check out the importance of purchasing excellent undercarriage parts, usual wear challenges dealt with by hefty machinery drivers, the advantages of timely substitutes, guidelines for choosing trusted providers, and essential maintenance pointers to extend the life expectancy of undercarriage parts.

Value of Top Quality Undercarriage Parts

Quality undercarriage parts are important elements in making sure the durability and efficiency of heavy machinery. The undercarriage of equipment such as excavators, bulldozers, and track loaders plays a vital function in sustaining the maker's weight, supplying security on different terrains, and taking in the effect of uneven surfaces. By buying top quality undercarriage parts, drivers can considerably prolong the lifespan of their machinery and reduce the threat of unanticipated failures.

One trick benefit of using quality undercarriage components is the improvement of general device performance. Sturdy tracks, idlers, rollers, and sprockets reduce rubbing and make sure smoother movement, ultimately bring about boosted efficiency and efficiency on work sites. Moreover, reliable undercarriage parts lessen downtime for repair and maintenance, allowing operators to maximize their functional hours and project target dates.

Typical Undercarriage Wear Problems

Advantages of Timely Replacement

One trick advantage of timely undercarriage part replacement is raised equipment uptime. By changing worn parts prior to they fall short, the danger of unforeseen break downs is minimized, reducing downtime for fixings and upkeep. This positive method not just maintains the heavy equipment functional but also protects against prospective damage to various other elements that could arise from a stopping working undercarriage.

Furthermore, changing undercarriage parts promptly can boost overall performance. A properly maintained undercarriage guarantees optimal maker performance, permitting smoother operation and greater effectiveness in finishing tasks. This, subsequently, causes enhanced work site performance and cost financial savings by avoiding hold-ups and interruptions triggered by underperforming machinery. As a result, spending in timely undercarriage component replacement is a positive method that settles in terms of enhanced efficiency and minimized operational costs.

Selecting the Right Undercarriage Distributor

Selecting the suitable undercarriage vendor is a critical decision that considerably affects the efficiency and upkeep of hefty equipment. When picking a supplier for undercarriage parts, several elements need to be taken into consideration to make certain optimal efficiency and cost-effectiveness. It is crucial to analyze the supplier's reputation and experience in the sector. A reliable provider with years of experience is much more likely to provide top notch components resource and trustworthy service. Furthermore, consider the series of items supplied by the vendor. A provider that provides a wide option of undercarriage components for different heavy equipment brand names and designs can be advantageous as it gives extra choices to meet specific demands.

In addition, assessing the distributor's client service and support is vital. A supplier that uses superb customer care, fast reaction times, and technological assistance can assist decrease downtime and ensure smooth operations. Expense is likewise a considerable element to think about; however, it ought to not be the single component. When selecting the appropriate undercarriage provider for heavy equipment, balancing dependability, top quality, and cost-effectiveness is vital. By carefully reviewing these elements, you can pick a vendor that satisfies your demands and adds to the effective performance and upkeep of your heavy machinery.

Maintenance Tips for Extended Lifespan

To ensure a prolonged life expectancy for heavy equipment undercarriage parts, executing a proactive upkeep regimen is essential. Frequently evaluating undercarriage components such as track chains, idlers, rollers, and sprockets for damage is important. Any indications of damages or too much wear must be without delay addressed to stop further wear and tear and potential failures. Additionally, maintaining the undercarriage tidy from dust, debris, and you could try this out harsh products can substantially prolong its lifespan. Oiling relocating components according to manufacturer recommendations assists lower rubbing and avoid early wear. Checking track stress and alignment is also important to protect against uneven wear on the undercarriage parts. Purchasing high quality undercarriage components from credible suppliers is equally crucial for ensuring longevity. By complying with these upkeep pointers vigilantly, heavy equipment proprietors can maximize the efficiency and resilience of their undercarriage parts, eventually minimizing downtime and functional Learn More Here prices.

Verdict

Finally, high quality undercarriage parts are vital for the efficient operation of hefty equipment. Timely replacement of used parts can avoid costly downtime and keep ideal performance. Choosing a reliable distributor and complying with appropriate maintenance techniques are essential to making sure the extended lifespan of undercarriage components. By attending to usual wear concerns and investing in premium parts, heavy machinery drivers can make the most of productivity and minimize upkeep costs.

Extreme wear and tear on undercarriage parts of hefty equipment can lead to considerable operational challenges and raised upkeep expenses. Regular examinations, proper maintenance, and prompt replacements of worn undercarriage components are vital to reduce these usual wear troubles and guarantee the optimal functioning of hefty machinery.

A distributor that uses a broad option of undercarriage components for various hefty equipment brands and versions can be beneficial as it gives a lot more options to fulfill particular demands.

By adhering to these maintenance tips carefully, heavy equipment proprietors can enhance the efficiency and sturdiness of their undercarriage parts, ultimately minimizing downtime and operational expenses.

Report this page